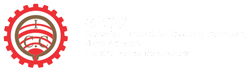

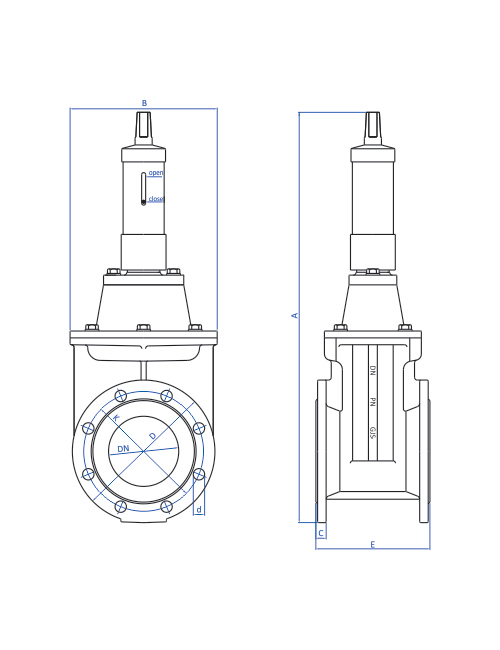

- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN600 from series F4 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC. -

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

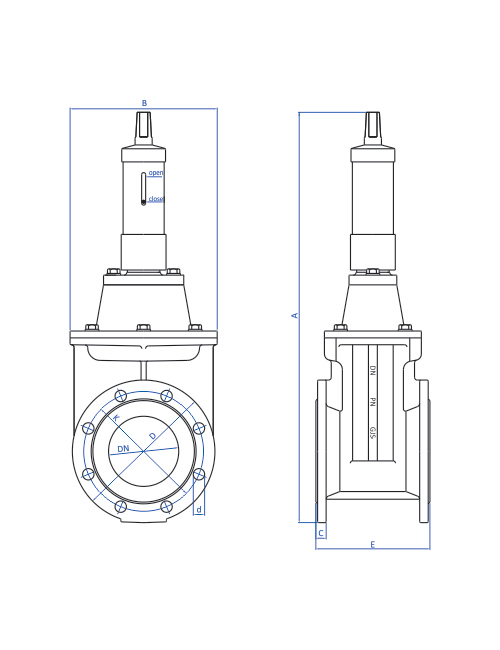

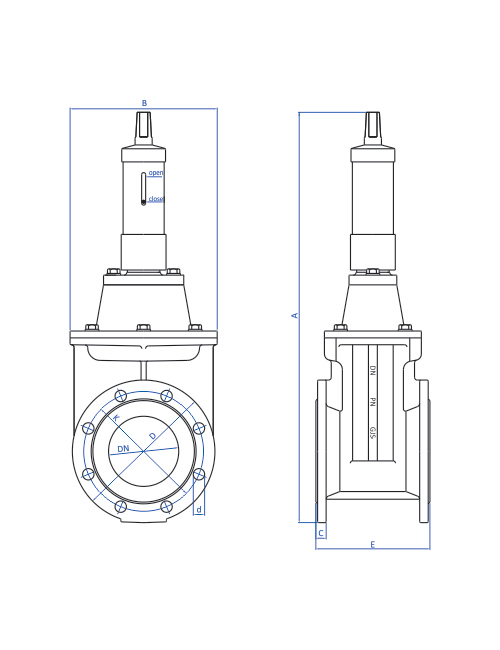

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN600 from series F4 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

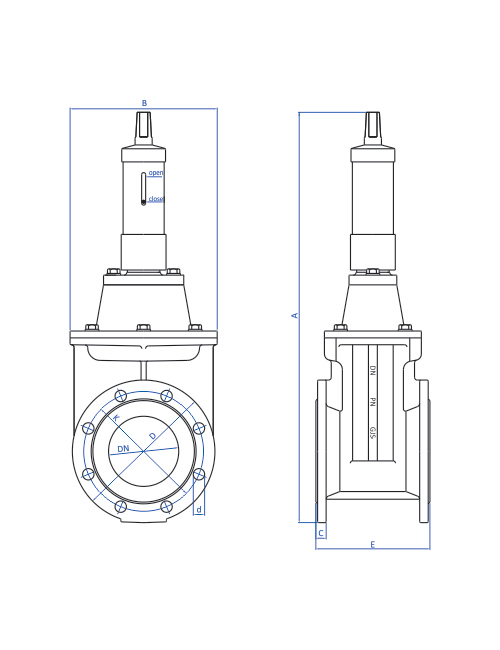

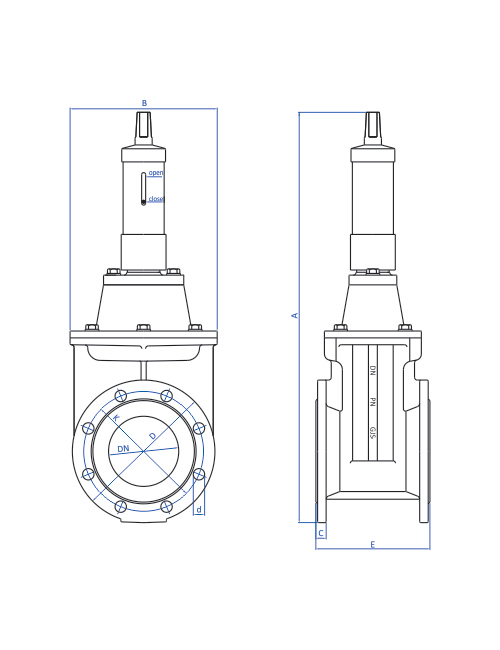

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN600 from series F4 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

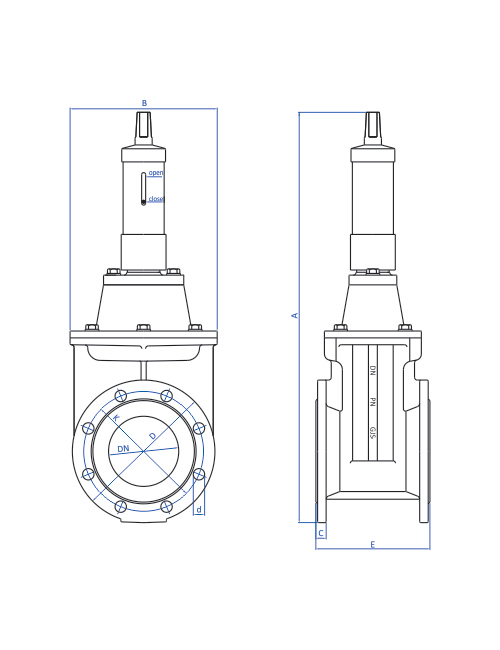

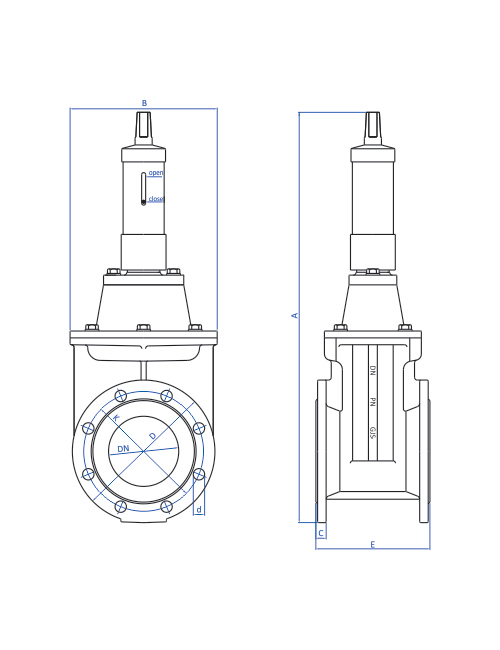

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN600 from series F4 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN600 from series F4 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN600 from series F4 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN600 from series F4 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN600 from series F4 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN600 from series F4 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN600 from series F4 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN600 from series F4 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN600 from series F4 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN600 from series F4 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN600 from series F4 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN300 from series F5 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN300 from series F5 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN300 from series F5 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN300 from series F5 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN300 from series F5 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN300 from series F5 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN300 from series F5 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN300 from series F5 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN300 from series F5 are available

-

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.

The valve is used in industrial and constructional fields for on/off purposes of drinking water and non-corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Wedge rubberized all over with EPEM according to DIN53538-5

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Sizes DN50 to DN600 from series F4 and DN50 to DN300 from series F5 are available

-

The valve is used for liquids flow on/off purposes in chemical industries, water purifiers chlorination stations, municipal and industrial sewage, pools and great scope of corrosive liquids with maximum temperature of 80oC.

The valve is used for liquids flow on/off purposes in chemical industries, water purifiers chlorination stations, municipal and industrial sewage, pools and great scope of corrosive liquids with maximum temperature of 80oC.- The valve parts, spindle disposition mechanism and sealing uniquely designed by AICC.

- Easy service with no need to detach the valve from the water line system

- Suitable for underground systems as heavy duty valve

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon reques

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Spindle made of stainless steel 1.4021 according to DIN17440 with rolled thread and ultra-burnished sealing surface

- Inside and outside surfaces covered with a minimum of 250 micron epoxy electrostatic paint coating according to DIN30677

- Rubberized wedge, all rubber parts, wedge nut and spindle are designed and selected based on the kind of liquid and operation circumstances for each application

- Anti-corrosion Valves series F4 and F5 sizes DN50 to DN300 are available (Dimension specification depends on each specific valve)

-

The valve is equipped with open/close indicator and designed for liquid flows on/off purposes.

The valve is equipped with open/close indicator and designed for liquid flows on/off purposes.- Anti-Corrosion and normal valves series F4 and F5 (short and long) Sizes DN50 to DN200 are available.

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for Pn25

-

The valve is equipped with open/close indicator and designed for liquid flows on/off purposes.

The valve is equipped with open/close indicator and designed for liquid flows on/off purposes.- Anti-Corrosion and normal valves series F4 and F5 (short and long) Sizes DN50 to DN200 are available.

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for Pn25

-

The valve is equipped with open/close indicator and designed for liquid flows on/off purposes.

The valve is equipped with open/close indicator and designed for liquid flows on/off purposes.- Anti-Corrosion and normal valves series F4 and F5 (short and long) Sizes DN50 to DN200 are available.

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for Pn25

-

The valve is equipped with open/close indicator and designed for liquid flows on/off purposes.

The valve is equipped with open/close indicator and designed for liquid flows on/off purposes.- Anti-Corrosion and normal valves series F4 and F5 (short and long) Sizes DN50 to DN200 are available.

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for Pn25

-

The valve is equipped with open/close indicator and designed for liquid flows on/off purposes.

The valve is equipped with open/close indicator and designed for liquid flows on/off purposes.- Anti-Corrosion and normal valves series F4 and F5 (short and long) Sizes DN50 to DN200 are available.

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for Pn25

-

The valve is equipped with open/close indicator and designed for liquid flows on/off purposes.

The valve is equipped with open/close indicator and designed for liquid flows on/off purposes.- Anti-Corrosion and normal valves series F4 and F5 (short and long) Sizes DN50 to DN200 are available.

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for Pn25

-

The valve is equipped with open/close indicator and designed for liquid flows on/off purposes.

The valve is equipped with open/close indicator and designed for liquid flows on/off purposes.- Anti-Corrosion and normal valves series F4 and F5 (short and long) Sizes DN50 to DN200 are available.

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for Pn25

-

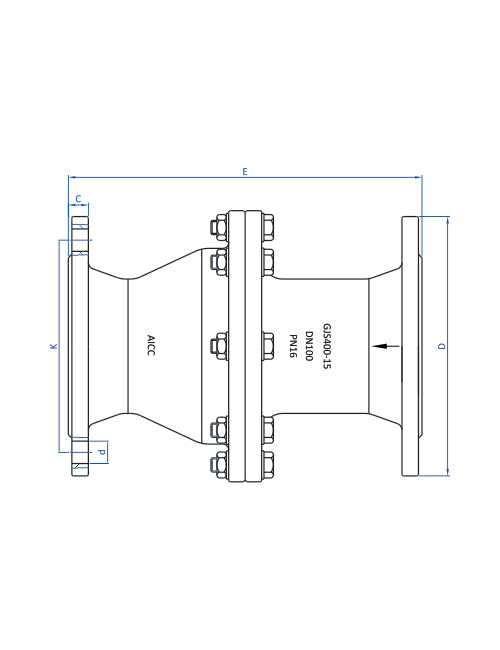

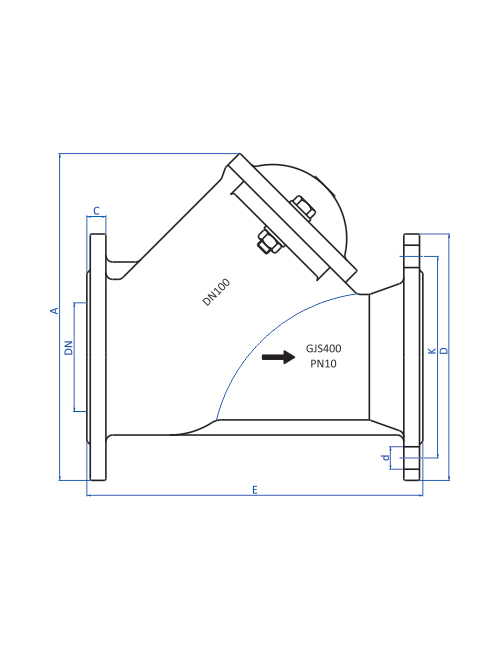

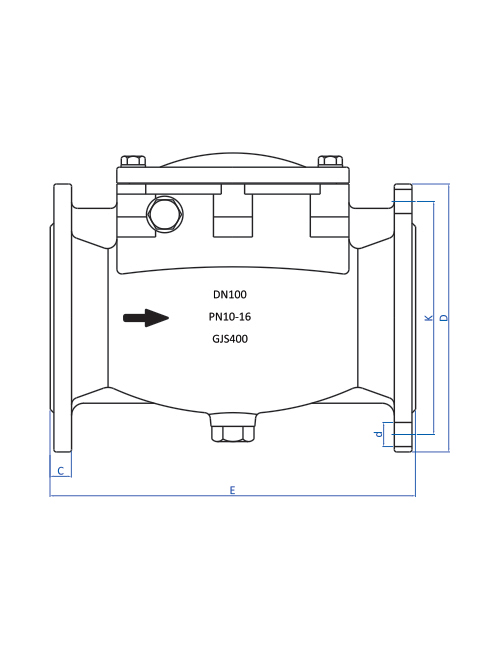

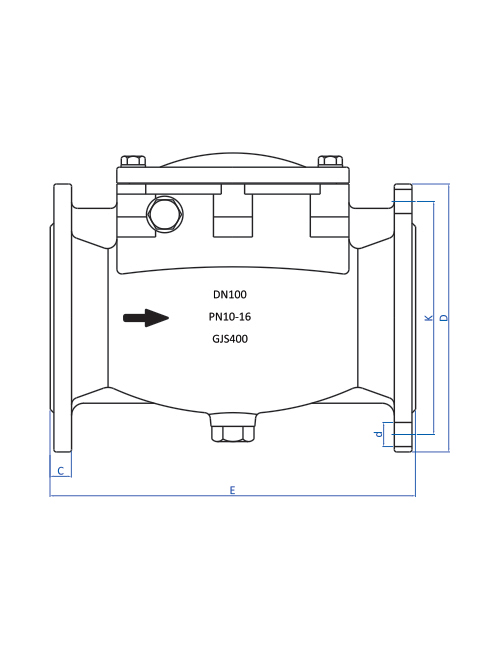

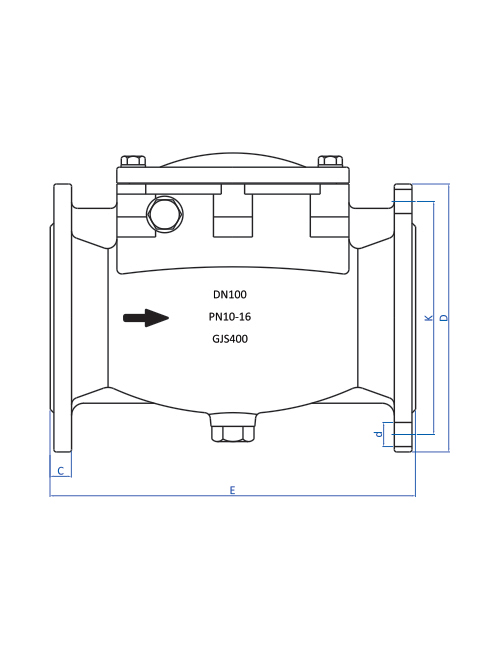

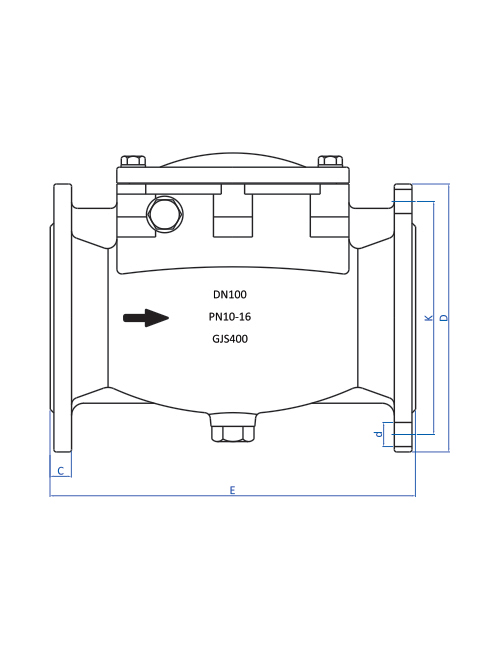

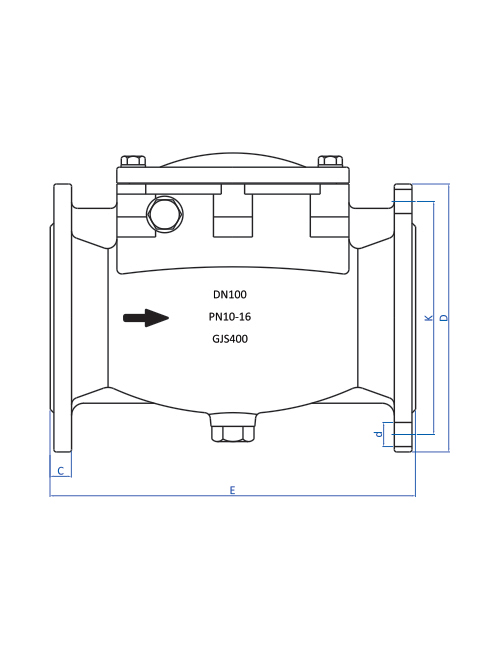

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

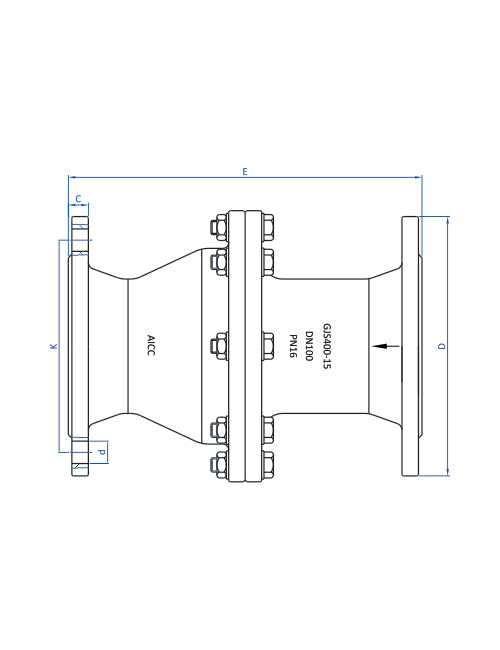

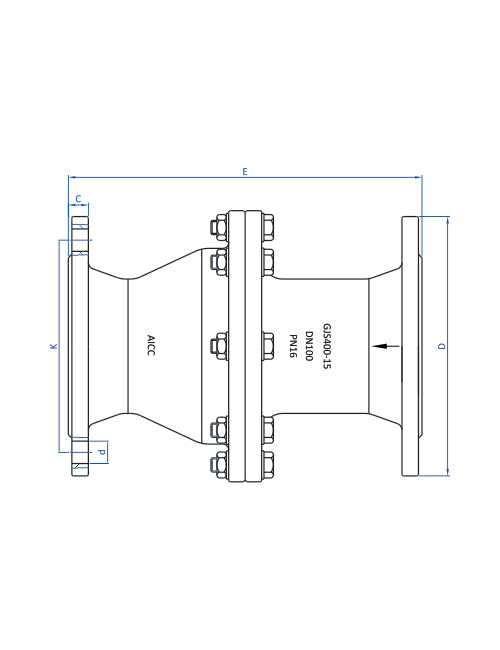

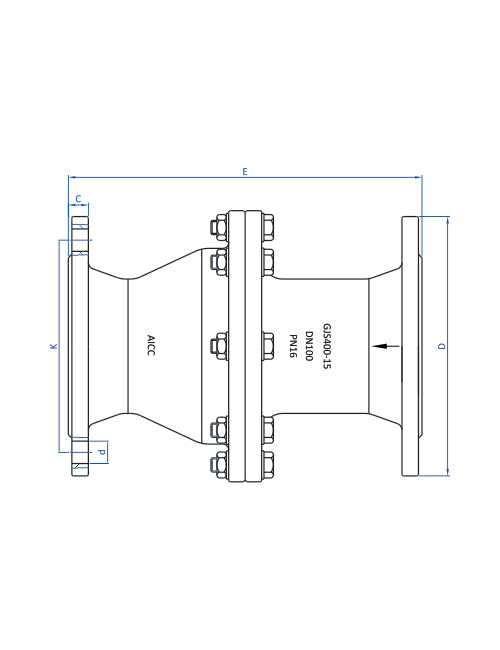

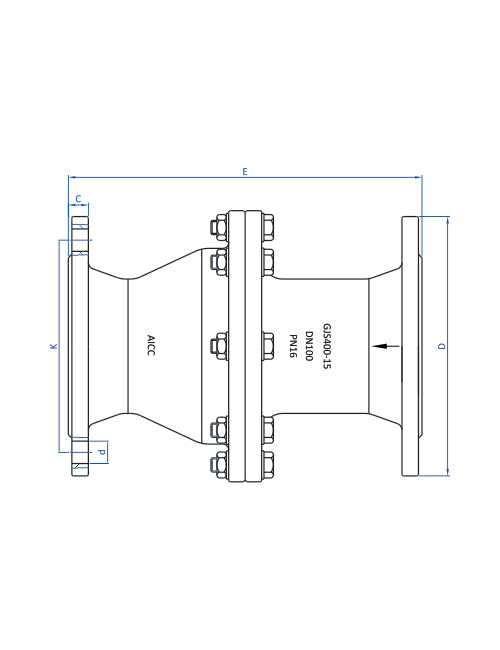

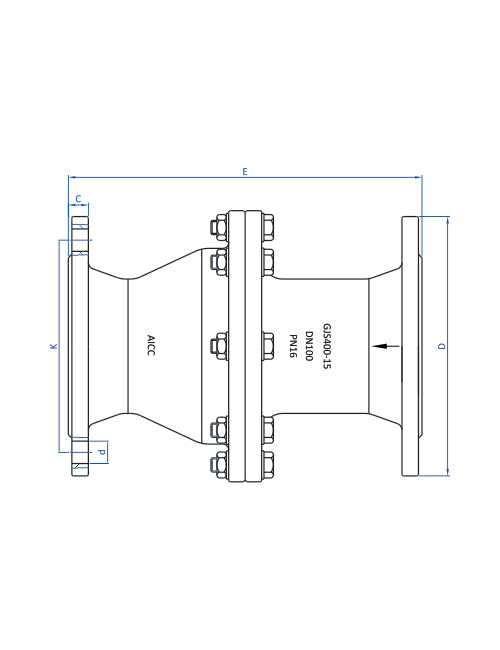

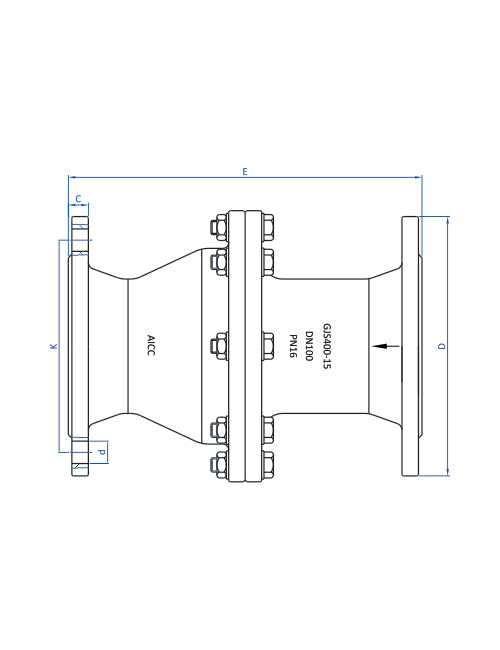

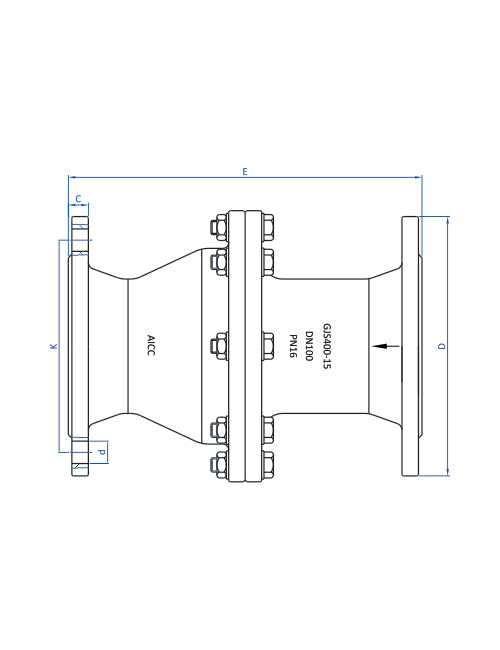

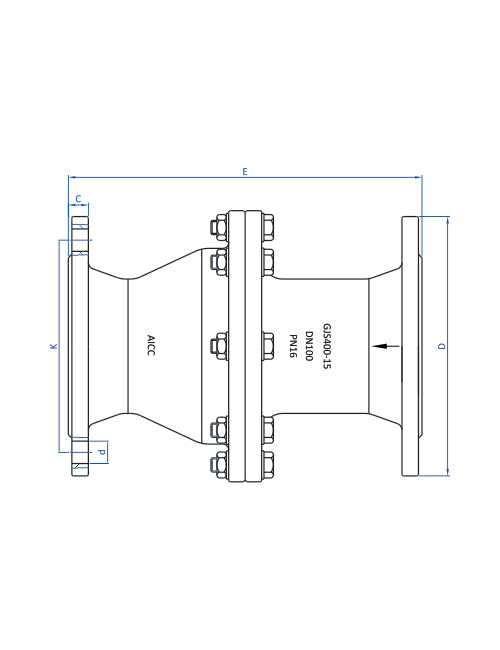

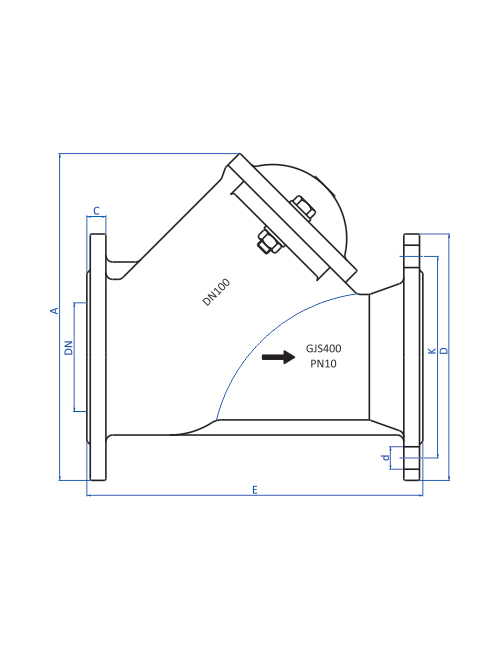

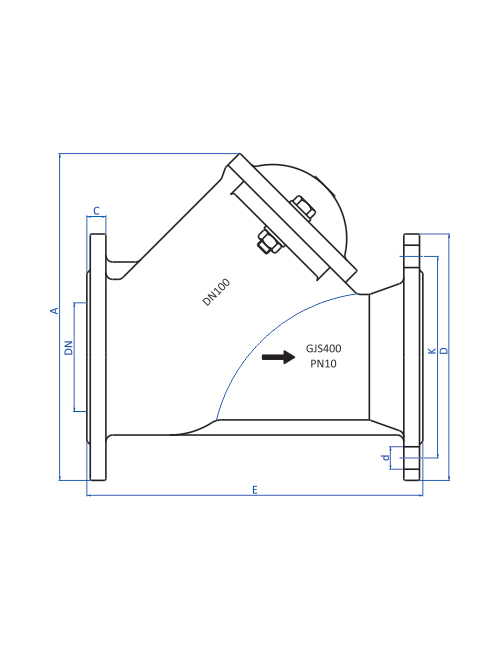

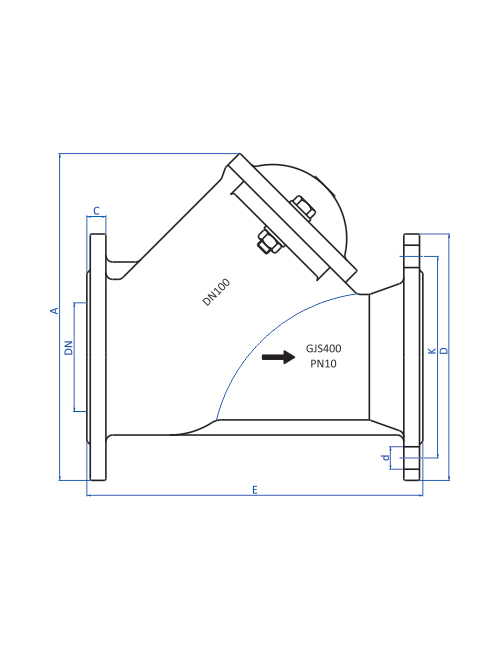

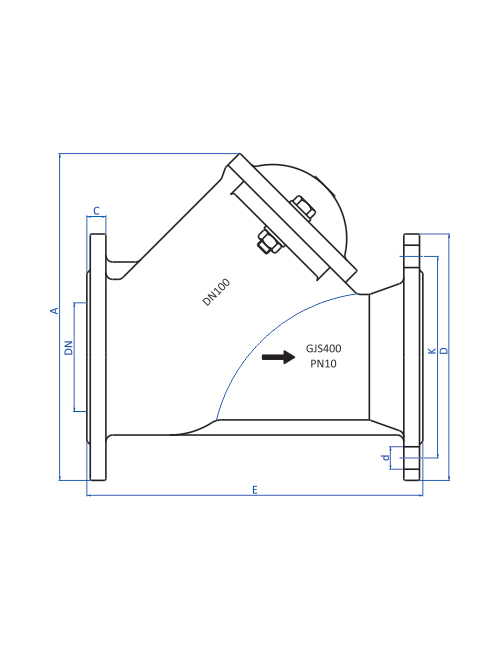

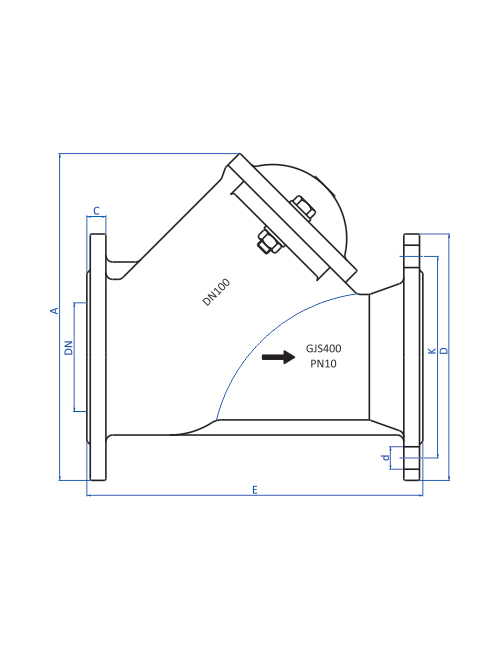

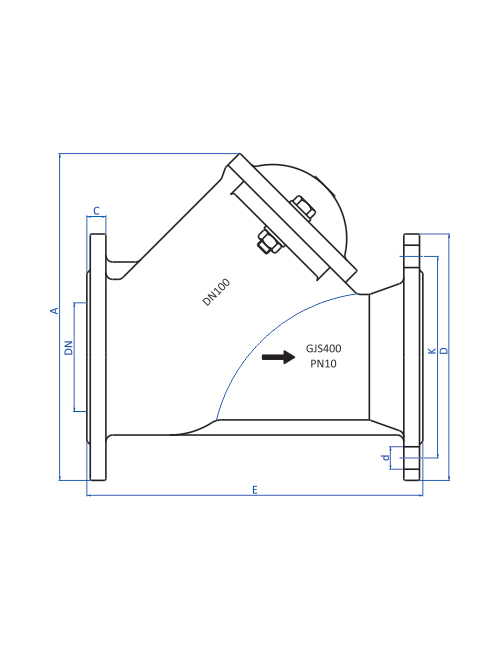

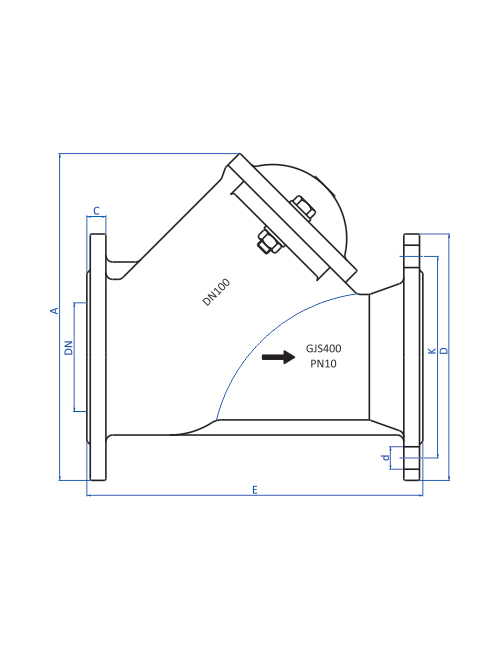

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC- This valve is exclusively designed by AICC to provide optimum service and operation

- Usable vertically or horizontally (Minimum pressure neede for sealing in horizontal status 1.5 Bar)

- Self-cleaning property due to continuous movement of the ball

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body made of ductile iron EN1563(GJS400)

- Disk made of ductile iron volcanized with EPDM rubber according to DIN53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

- When installing valve, attention should be paid to the direction of arrow on the body.

-

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC- This valve is exclusively designed by AICC to provide optimum service and operation

- Usable vertically or horizontally (Minimum pressure neede for sealing in horizontal status 1.5 Bar)

- Self-cleaning property due to continuous movement of the ball

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body made of ductile iron EN1563(GJS400)

- Disk made of ductile iron volcanized with EPDM rubber according to DIN53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

- When installing valve, attention should be paid to the direction of arrow on the body.

-

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC- This valve is exclusively designed by AICC to provide optimum service and operation

- Usable vertically or horizontally (Minimum pressure neede for sealing in horizontal status 1.5 Bar)

- Self-cleaning property due to continuous movement of the ball

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body made of ductile iron EN1563(GJS400)

- Disk made of ductile iron volcanized with EPDM rubber according to DIN53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

- When installing valve, attention should be paid to the direction of arrow on the body.

-

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC- This valve is exclusively designed by AICC to provide optimum service and operation

- Usable vertically or horizontally (Minimum pressure neede for sealing in horizontal status 1.5 Bar)

- Self-cleaning property due to continuous movement of the ball

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body made of ductile iron EN1563(GJS400)

- Disk made of ductile iron volcanized with EPDM rubber according to DIN53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

- When installing valve, attention should be paid to the direction of arrow on the body.

-

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC- This valve is exclusively designed by AICC to provide optimum service and operation

- Usable vertically or horizontally (Minimum pressure neede for sealing in horizontal status 1.5 Bar)

- Self-cleaning property due to continuous movement of the ball

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body made of ductile iron EN1563(GJS400)

- Disk made of ductile iron volcanized with EPDM rubber according to DIN53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

- When installing valve, attention should be paid to the direction of arrow on the body.

-

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC- This valve is exclusively designed by AICC to provide optimum service and operation

- Usable vertically or horizontally (Minimum pressure neede for sealing in horizontal status 1.5 Bar)

- Self-cleaning property due to continuous movement of the ball

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body made of ductile iron EN1563(GJS400)

- Disk made of ductile iron volcanized with EPDM rubber according to DIN53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

- When installing valve, attention should be paid to the direction of arrow on the body.

-

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC- This valve is exclusively designed by AICC to provide optimum service and operation

- Usable vertically or horizontally (Minimum pressure neede for sealing in horizontal status 1.5 Bar)

- Self-cleaning property due to continuous movement of the ball

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body made of ductile iron EN1563(GJS400)

- Disk made of ductile iron volcanized with EPDM rubber according to DIN53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

- When installing valve, attention should be paid to the direction of arrow on the body.

-

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC

The valve is used in industrial, agricultural and water line systems, potable water, pump stations, municipal and industrial sewage for non-corrosive liquids with maximum temperature of 80oC- This valve is exclusively designed by AICC to provide optimum service and operation

- Usable vertically or horizontally (Minimum pressure neede for sealing in horizontal status 1.5 Bar)

- Self-cleaning property due to continuous movement of the ball

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body made of ductile iron EN1563(GJS400)

- Disk made of ductile iron volcanized with EPDM rubber according to DIN53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

- When installing valve, attention should be paid to the direction of arrow on the body.

-

The valve is used in industrial, agricultural and water line systems, potable water, pump stations for non-corrosive liquids with maximum temperature of 80oC

The valve is used in industrial, agricultural and water line systems, potable water, pump stations for non-corrosive liquids with maximum temperature of 80oC- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to EN 558-1

- Body made of ductile iron EN1563(GJS400)

- The Blocking ball made of Aluminum volcanized with EPDM according to DIN53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

The valve is used in industrial, agricultural and water line systems, potable water, pump stations for non-corrosive liquids with maximum temperature of 80oC

The valve is used in industrial, agricultural and water line systems, potable water, pump stations for non-corrosive liquids with maximum temperature of 80oC- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to EN 558-1

- Body made of ductile iron EN1563(GJS400)

- The Blocking ball made of Aluminum volcanized with EPDM according to DIN53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

The valve is used in industrial, agricultural and water line systems, potable water, pump stations for non-corrosive liquids with maximum temperature of 80oC

The valve is used in industrial, agricultural and water line systems, potable water, pump stations for non-corrosive liquids with maximum temperature of 80oC- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to EN 558-1

- Body made of ductile iron EN1563(GJS400)

- The Blocking ball made of Aluminum volcanized with EPDM according to DIN53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

The valve is used in industrial, agricultural and water line systems, potable water, pump stations for non-corrosive liquids with maximum temperature of 80oC

The valve is used in industrial, agricultural and water line systems, potable water, pump stations for non-corrosive liquids with maximum temperature of 80oC- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to EN 558-1

- Body made of ductile iron EN1563(GJS400)

- The Blocking ball made of Aluminum volcanized with EPDM according to DIN53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

The valve is used in industrial, agricultural and water line systems, potable water, pump stations for non-corrosive liquids with maximum temperature of 80oC

The valve is used in industrial, agricultural and water line systems, potable water, pump stations for non-corrosive liquids with maximum temperature of 80oC- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to EN 558-1

- Body made of ductile iron EN1563(GJS400)

- The Blocking ball made of Aluminum volcanized with EPDM according to DIN53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

The valve is used in industrial, agricultural and water line systems, potable water, pump stations for non-corrosive liquids with maximum temperature of 80oC

The valve is used in industrial, agricultural and water line systems, potable water, pump stations for non-corrosive liquids with maximum temperature of 80oC- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to EN 558-1

- Body made of ductile iron EN1563(GJS400)

- The Blocking ball made of Aluminum volcanized with EPDM according to DIN53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

The valve is used in industrial, agricultural and water line systems, potable water, pump stations for non-corrosive liquids with maximum temperature of 80oC

The valve is used in industrial, agricultural and water line systems, potable water, pump stations for non-corrosive liquids with maximum temperature of 80oC- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to EN 558-1

- Body made of ductile iron EN1563(GJS400)

- The Blocking ball made of Aluminum volcanized with EPDM according to DIN53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Usable for water flow on/off purposes in agriculture and pools as on irrigation hydrant valve.

Usable for water flow on/off purposes in agriculture and pools as on irrigation hydrant valve.- Full bore valve (Seatless)

- Low price, light weight, reliable structure, easy service and handling.

- Body made of ductile iron EN1563(GJS400)

- Disk made of ductile iron volcanized with EPDM rubber according to DIN 53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Usable for water flow on/off purposes in agriculture and pools as on irrigation hydrant valve.

Usable for water flow on/off purposes in agriculture and pools as on irrigation hydrant valve.- Full bore valve (Seatless)

- Low price, light weight, reliable structure, easy service and handling.

- Body made of ductile iron EN1563(GJS400)

- Disk made of ductile iron volcanized with EPDM rubber according to DIN 53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Usable for water flow on/off purposes in agriculture and pools as on irrigation hydrant valve.

Usable for water flow on/off purposes in agriculture and pools as on irrigation hydrant valve.- Full bore valve (Seatless)

- Low price, light weight, reliable structure, easy service and handling.

- Body made of ductile iron EN1563(GJS400)

- Disk made of ductile iron volcanized with EPDM rubber according to DIN 53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Usable for water flow on/off purposes in agriculture and pools as on irrigation hydrant valve.

Usable for water flow on/off purposes in agriculture and pools as on irrigation hydrant valve.- Full bore valve (Seatless)

- Low price, light weight, reliable structure, easy service and handling.

- Body made of ductile iron EN1563(GJS400)

- Disk made of ductile iron volcanized with EPDM rubber according to DIN 53538-5

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677