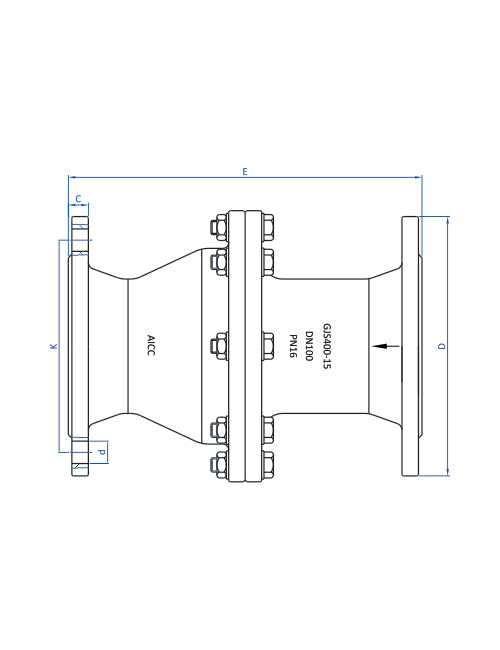

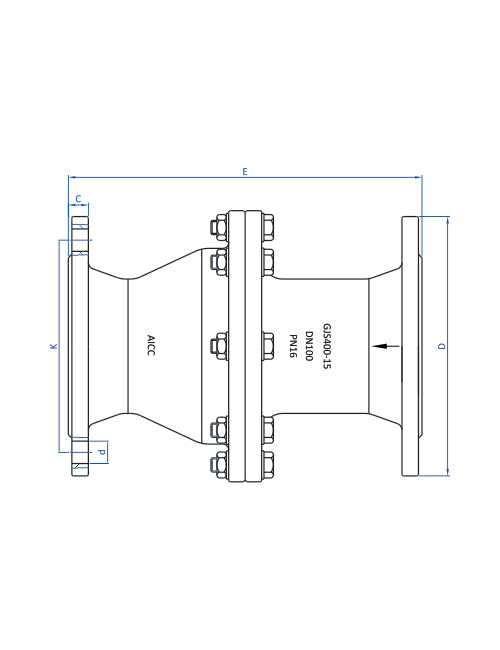

- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

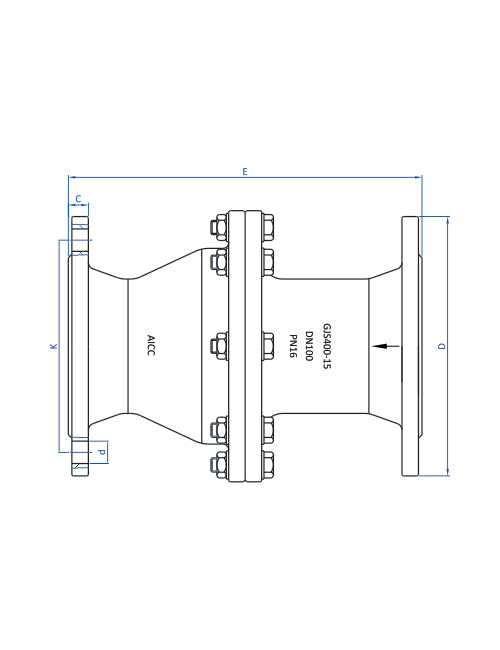

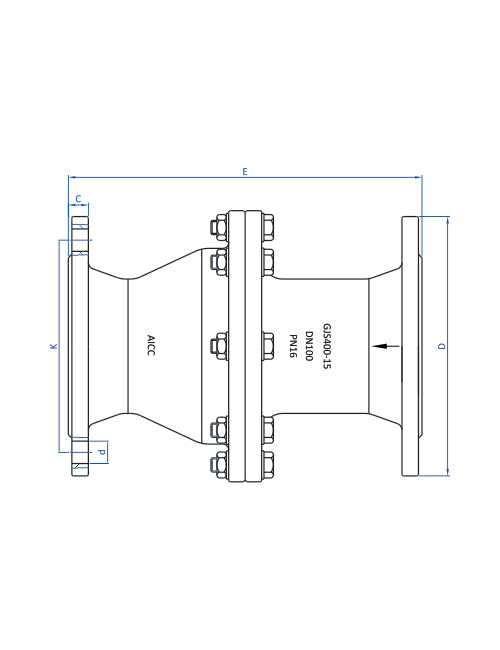

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects -

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

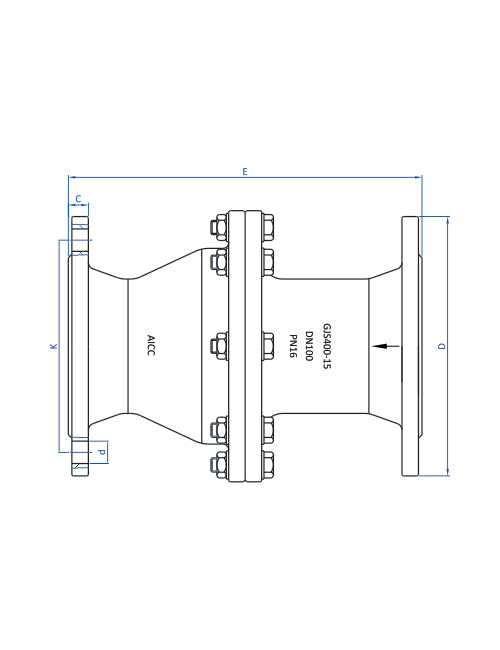

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

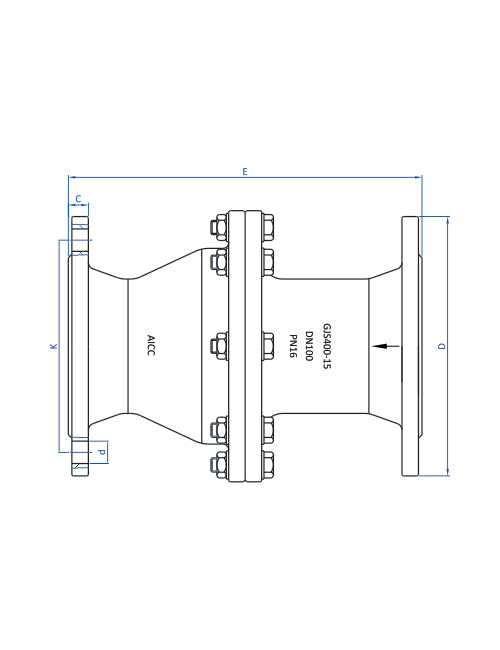

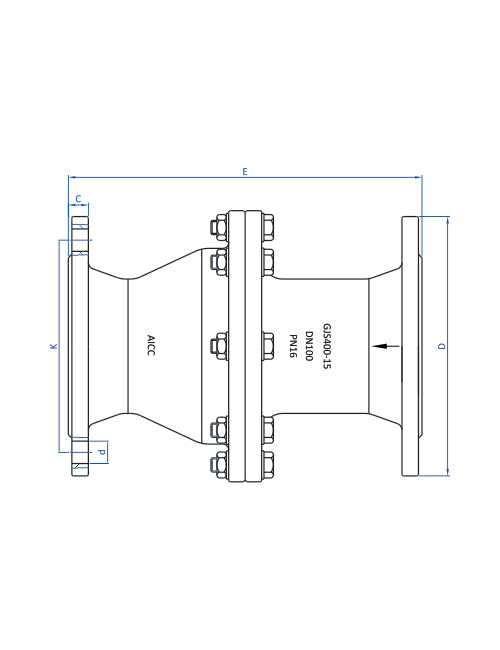

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

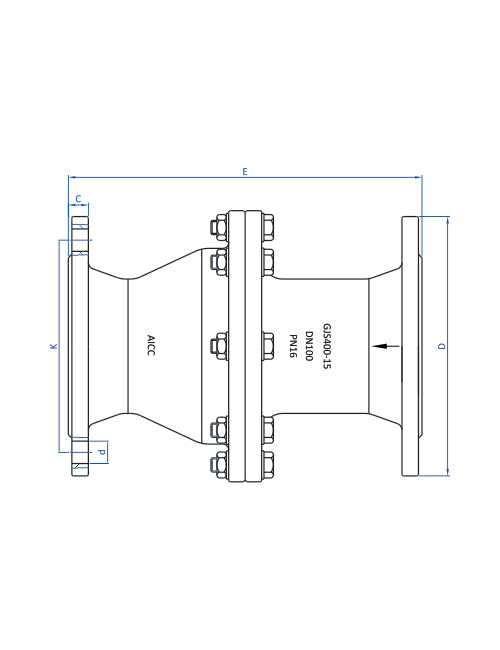

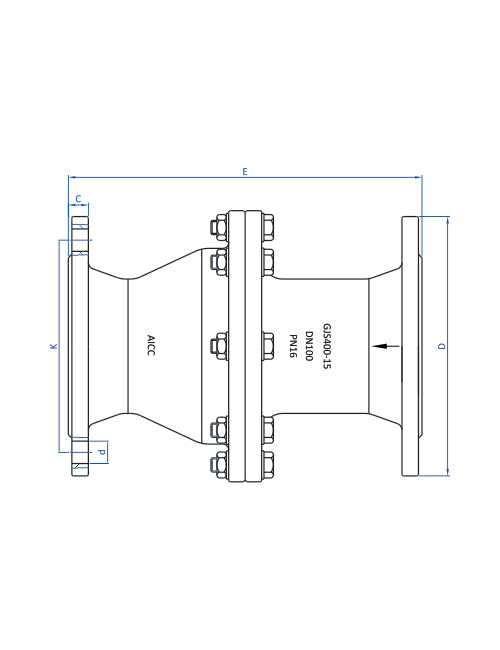

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects

Used in industrial and constructional fields and pumping stations for one-way flow of potable water and non-corrosive liquids with maximum temperature of 80oC; prevents back flow of liquids and hammer effects- Closing technique designed and Trimmed uniquely by AICC in order to prevent back flow of the liquid and its harmful and damaging impact

- Suitable for installing in different positions (Vertically or horizontally)

- Drilling and dimension of flanges according to EN 1092-2 and other standards upon request

- Body made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- Blocking Disk made of ductile iron volcanized with EPDM according to DIN53538-5 perfectly resistant against hammer effects

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Spindle made of stainless steel 1.4021 according to DIN17440

- Spring made of stainless steel according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677