- suitable for use with water and neutral liquids, to a maximum temperature +80oC.

- Designed and manufactured according to DIN3352-4 and ISIRI3363

- Flanges drilled according to ASME B16.5 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body, wedge and bonnet made of ductile iron EN1563(GJS400) for PN10/16 and EN1563(GJS500) for PN25

- The remaining features of the valve depend on each specific model

-

The valve is used in fire safety systems, oil, gas, and petrochemical industries and power plants for on/off purposes.

The valve is used in fire safety systems, oil, gas, and petrochemical industries and power plants for on/off purposes. -

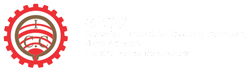

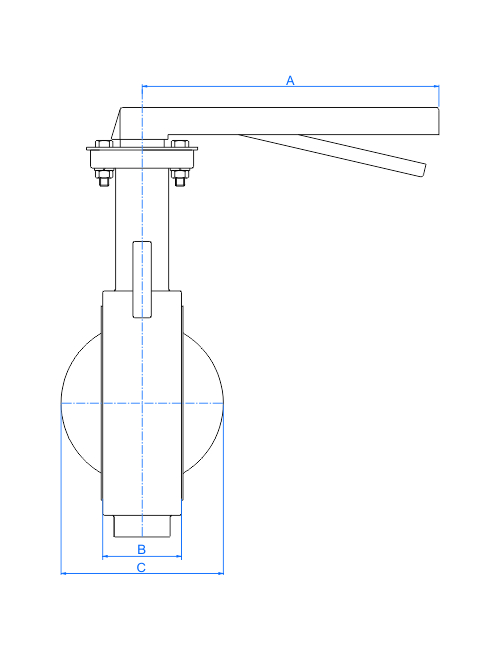

Application:

Application:- Isolating

- Flow control (Maximum flow velocity 3 m/s)

- Easy installation and maintenance, low pressure drop.

- Suitable installation between flanges that are drilled in accordance with EN1092-2 or ASME B 16.5 without need of sealing washer for installation.

- Body and disc made of ductile iron EN1563 (GJS 400)

- Seat made of wear resistant EPDM rubber DIN53538-5

- Possibility of installation in any desired position.

-

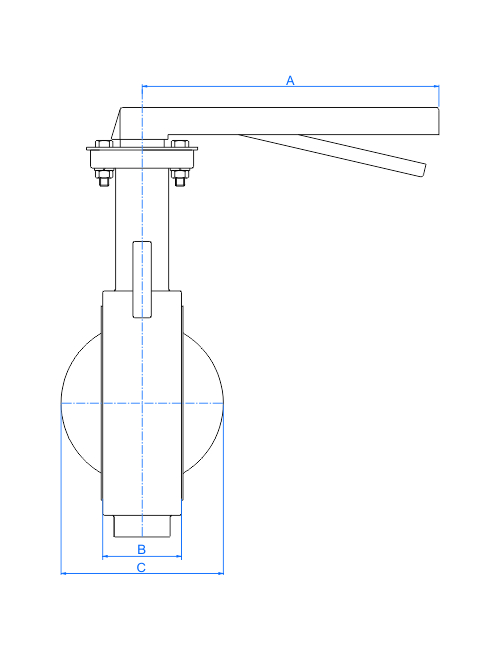

Application:

Application:- Isolating

- Flow control (Maximum flow velocity 3 m/s)

- Easy installation and maintenance, low pressure drop.

- Suitable installation between flanges that are drilled in accordance with EN1092-2 or ASME B 16.5 without need of sealing washer for installation.

- Body and disc made of ductile iron EN1563 (GJS 400)

- Seat made of wear resistant EPDM rubber DIN53538-5

- Possibility of installation in any desired position.

-

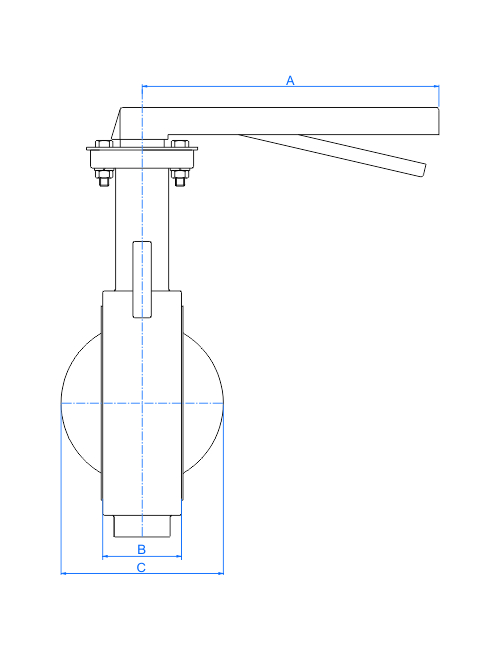

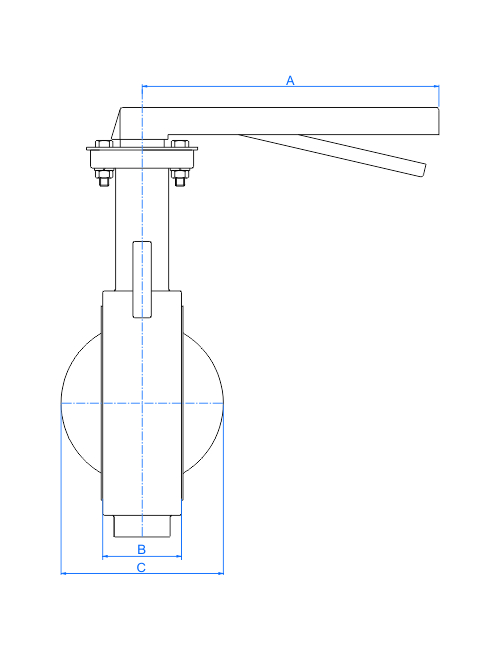

Application:

Application:- Isolating

- Flow control (Maximum flow velocity 3 m/s)

- Easy installation and maintenance, low pressure drop.

- Suitable installation between flanges that are drilled in accordance with EN1092-2 or ASME B 16.5 without need of sealing washer for installation.

- Body and disc made of ductile iron EN1563 (GJS 400)

- Seat made of wear resistant EPDM rubber DIN53538-5

- Possibility of installation in any desired position.

-

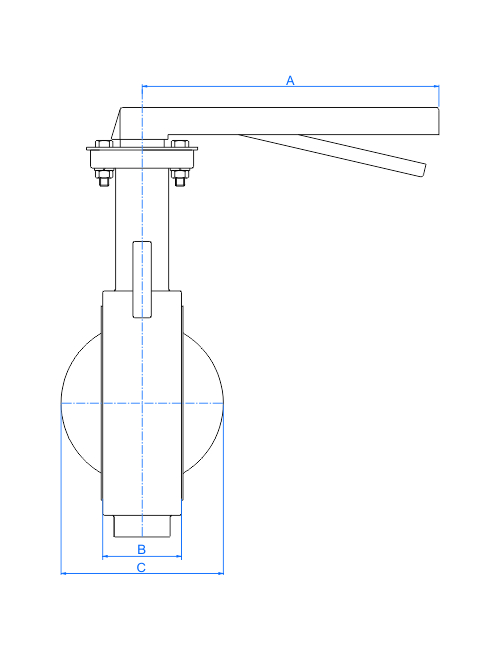

Application:

Application:- Isolating

- Flow control (Maximum flow velocity 3 m/s)

- Easy installation and maintenance, low pressure drop.

- Suitable installation between flanges that are drilled in accordance with EN1092-2 or ASME B 16.5 without need of sealing washer for installation.

- Body and disc made of ductile iron EN1563 (GJS 400)

- Seat made of wear resistant EPDM rubber DIN53538-5

- Possibility of installation in any desired position.

-

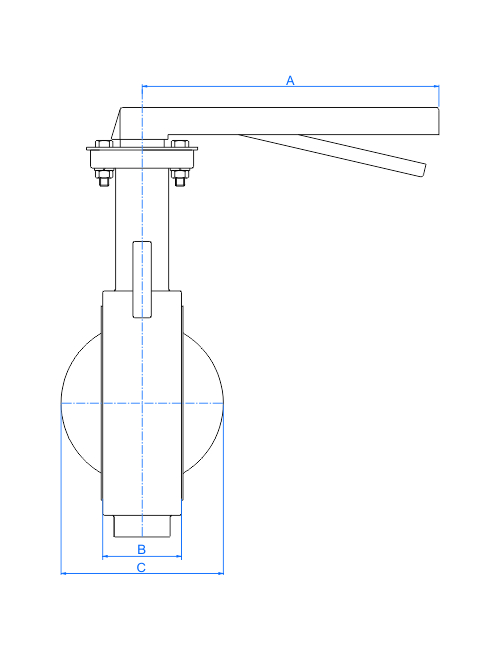

Application:

Application:- Isolating

- Flow control (Maximum flow velocity 3 m/s)

- Easy installation and maintenance, low pressure drop.

- Suitable installation between flanges that are drilled in accordance with EN1092-2 or ASME B 16.5 without need of sealing washer for installation.

- Body and disc made of ductile iron EN1563 (GJS 400)

- Seat made of wear resistant EPDM rubber DIN53538-5

- Possibility of installation in any desired position.

-

Application:

Application:- Isolating

- Flow control (Maximum flow velocity 3 m/s)

- Easy installation and maintenance, low pressure drop.

- Suitable installation between flanges that are drilled in accordance with EN1092-2 or ASME B 16.5 without need of sealing washer for installation.

- Body and disc made of ductile iron EN1563 (GJS 400)

- Seat made of wear resistant EPDM rubber DIN53538-5

- Possibility of installation in any desired position.

-

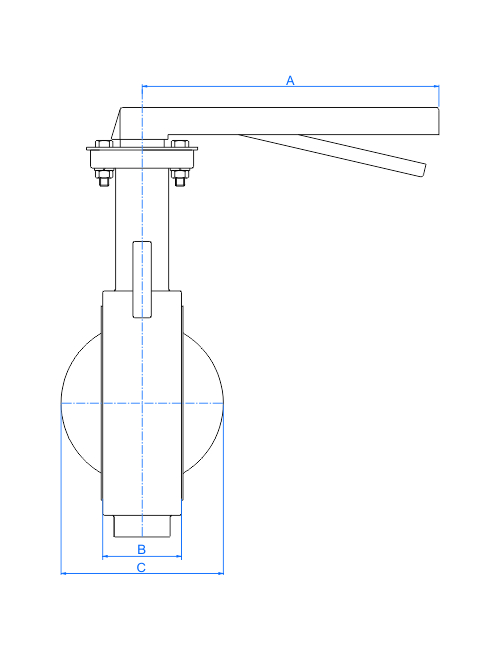

Application:

Application:- Isolating

- Flow control (Maximum flow velocity 3 m/s)

- Easy installation and maintenance, low pressure drop.

- Suitable installation between flanges that are drilled in accordance with EN1092-2 or ASME B 16.5 without need of sealing washer for installation.

- Body and disc made of ductile iron EN1563 (GJS 400)

- Seat made of wear resistant EPDM rubber DIN53538-5

- Possibility of installation in any desired position.

-

Application:

Application:- Isolating

- Flow control (Maximum flow velocity 3 m/s)

- Easy installation and maintenance, low pressure drop.

- Suitable installation between flanges that are drilled in accordance with EN1092-2 or ASME B 16.5 without need of sealing washer for installation.

- Body and disc made of ductile iron EN1563 (GJS 400)

- Seat made of wear resistant EPDM rubber DIN53538-5

- Possibility of installation in any desired position.

-

- The valve is used in industrial, agricultural and water line system, potable water, pump station with maximum temperature of 80oC.

- Easy installation and maintenance, low pressure drop.

- Full bore valve

- Self cleaning property due to continuous movement of the ball.

- Excellent resistant to erosion and corrosion.

- Drilling and dimension of flanges according to (EN558-1) DIN3202-1

- Body mad of ductile iron EN1563 (GJS400)

- Ball made of Aluminum volcanized with EPDM according to DIN53538-5 resistant against friction and hammer effect.

- Stainless steel filter AISI304 according to DIN17440 with 5mm diameter of hole.

- Inside and outside surfaced of body with a minimum of 250 micron epoxy electrostatic method coating according DIN30677

-

- The valve is used in industrial, agricultural and water line system, potable water, pump station with maximum temperature of 80oC.

- Easy installation and maintenance, low pressure drop.

- Full bore valve

- Self cleaning property due to continuous movement of the ball.

- Excellent resistant to erosion and corrosion.

- Drilling and dimension of flanges according to (EN558-1) DIN3202-1

- Body mad of ductile iron EN1563 (GJS400)

- Ball made of Aluminum volcanized with EPDM according to DIN53538-5 resistant against friction and hammer effect.

- Stainless steel filter AISI304 according to DIN17440 with 5mm diameter of hole.

- Inside and outside surfaced of body with a minimum of 250 micron epoxy electrostatic method coating according DIN30677

-

- The valve is used in industrial, agricultural and water line system, potable water, pump station with maximum temperature of 80oC.

- Easy installation and maintenance, low pressure drop.

- Full bore valve

- Self cleaning property due to continuous movement of the ball.

- Excellent resistant to erosion and corrosion.

- Drilling and dimension of flanges according to (EN558-1) DIN3202-1

- Body mad of ductile iron EN1563 (GJS400)

- Ball made of Aluminum volcanized with EPDM according to DIN53538-5 resistant against friction and hammer effect.

- Stainless steel filter AISI304 according to DIN17440 with 5mm diameter of hole.

- Inside and outside surfaced of body with a minimum of 250 micron epoxy electrostatic method coating according DIN30677

-

- The valve is used in industrial, agricultural and water line system, potable water, pump station with maximum temperature of 80oC.

- Easy installation and maintenance, low pressure drop.

- Full bore valve

- Self cleaning property due to continuous movement of the ball.

- Excellent resistant to erosion and corrosion.

- Drilling and dimension of flanges according to (EN558-1) DIN3202-1

- Body mad of ductile iron EN1563 (GJS400)

- Ball made of Aluminum volcanized with EPDM according to DIN53538-5 resistant against friction and hammer effect.

- Stainless steel filter AISI304 according to DIN17440 with 5mm diameter of hole.

- Inside and outside surfaced of body with a minimum of 250 micron epoxy electrostatic method coating according DIN30677

-

- The valve is used in industrial, agricultural and water line system, potable water, pump station with maximum temperature of 80oC.

- Easy installation and maintenance, low pressure drop.

- Full bore valve

- Self cleaning property due to continuous movement of the ball.

- Excellent resistant to erosion and corrosion.

- Drilling and dimension of flanges according to (EN558-1) DIN3202-1

- Body mad of ductile iron EN1563 (GJS400)

- Ball made of Aluminum volcanized with EPDM according to DIN53538-5 resistant against friction and hammer effect.

- Stainless steel filter AISI304 according to DIN17440 with 5mm diameter of hole.

- Inside and outside surfaced of body with a minimum of 250 micron epoxy electrostatic method coating according DIN30677

-

- The valve is used in industrial, agricultural and water line system, potable water, pump station with maximum temperature of 80oC.

- Easy installation and maintenance, low pressure drop.

- Full bore valve

- Self cleaning property due to continuous movement of the ball.

- Excellent resistant to erosion and corrosion.

- Drilling and dimension of flanges according to (EN558-1) DIN3202-1

- Body mad of ductile iron EN1563 (GJS400)

- Ball made of Aluminum volcanized with EPDM according to DIN53538-5 resistant against friction and hammer effect.

- Stainless steel filter AISI304 according to DIN17440 with 5mm diameter of hole.

- Inside and outside surfaced of body with a minimum of 250 micron epoxy electrostatic method coating according DIN30677

-

- The valve is used in industrial, agricultural and water line system, potable water, pump station with maximum temperature of 80oC.

- Easy installation and maintenance, low pressure drop.

- Full bore valve

- Self cleaning property due to continuous movement of the ball.

- Excellent resistant to erosion and corrosion.

- Drilling and dimension of flanges according to (EN558-1) DIN3202-1

- Body mad of ductile iron EN1563 (GJS400)

- Ball made of Aluminum volcanized with EPDM according to DIN53538-5 resistant against friction and hammer effect.

- Stainless steel filter AISI304 according to DIN17440 with 5mm diameter of hole.

- Inside and outside surfaced of body with a minimum of 250 micron epoxy electrostatic method coating according DIN30677

-

- The valve is used in industrial, agricultural and water line system, potable water, pump station with maximum temperature of 80oC.

- Easy installation and maintenance, low pressure drop.

- Full bore valve

- Self cleaning property due to continuous movement of the ball.

- Excellent resistant to erosion and corrosion.

- Drilling and dimension of flanges according to (EN558-1) DIN3202-1

- Body mad of ductile iron EN1563 (GJS400)

- Ball made of Aluminum volcanized with EPDM according to DIN53538-5 resistant against friction and hammer effect.

- Stainless steel filter AISI304 according to DIN17440 with 5mm diameter of hole.

- Inside and outside surfaced of body with a minimum of 250 micron epoxy electrostatic method coating according DIN30677

-

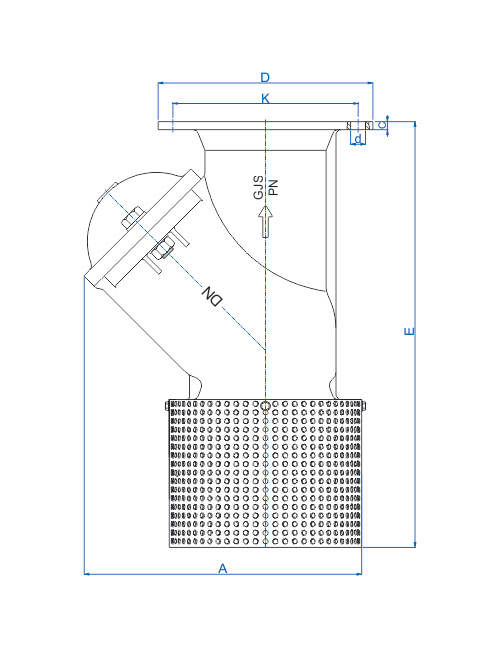

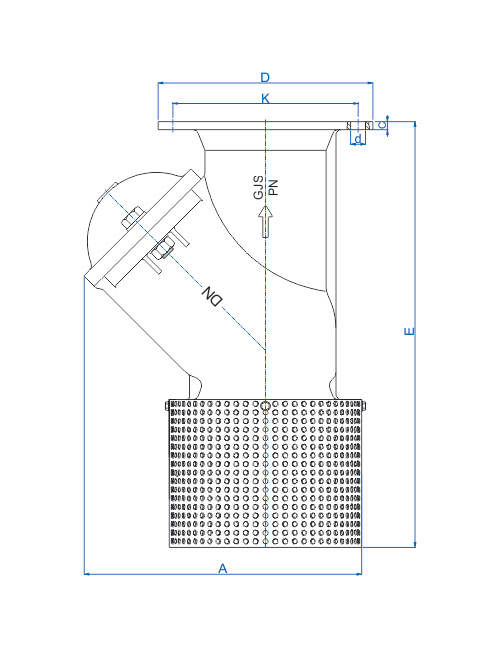

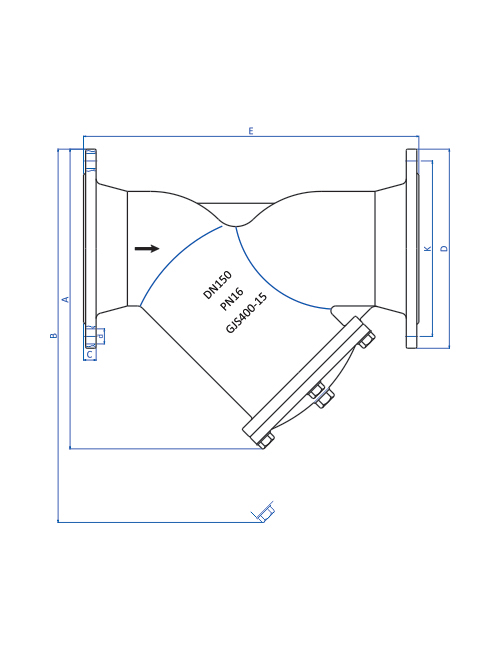

It is used in industrial, agricultural and water line systems, potable water and pump stations for non-corrosive liquids with maximum temperature of 80oC in order to prevent suspended particles enter the water network

It is used in industrial, agricultural and water line systems, potable water and pump stations for non-corrosive liquids with maximum temperature of 80oC in order to prevent suspended particles enter the water network- Flanges Drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body made of ductile iron EN1563(GJS400)

- Stainless steel filter AISI304 according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

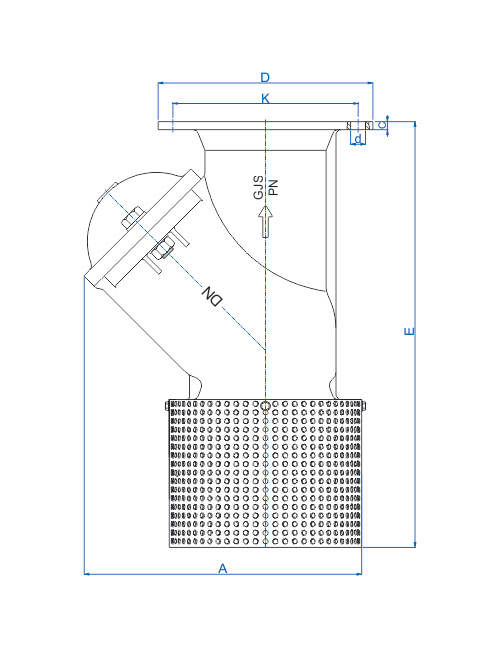

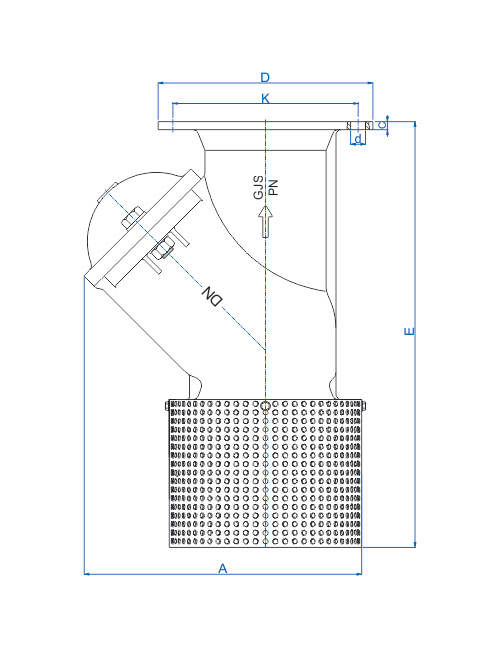

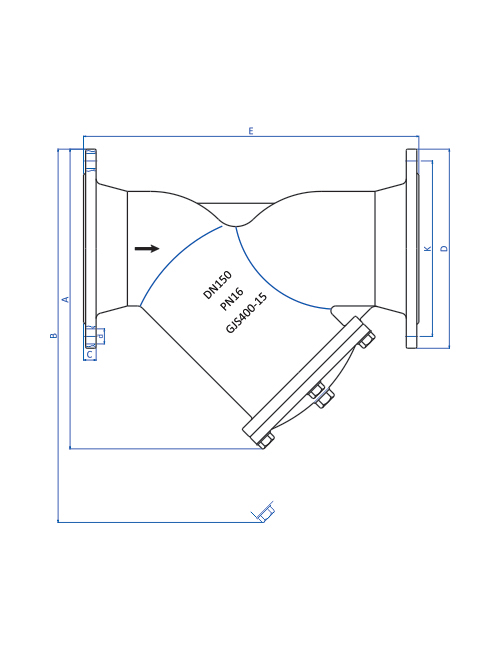

It is used in industrial, agricultural and water line systems, potable water and pump stations for non-corrosive liquids with maximum temperature of 80oC in order to prevent suspended particles enter the water network

It is used in industrial, agricultural and water line systems, potable water and pump stations for non-corrosive liquids with maximum temperature of 80oC in order to prevent suspended particles enter the water network- Flanges Drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body made of ductile iron EN1563(GJS400)

- Stainless steel filter AISI304 according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677

-

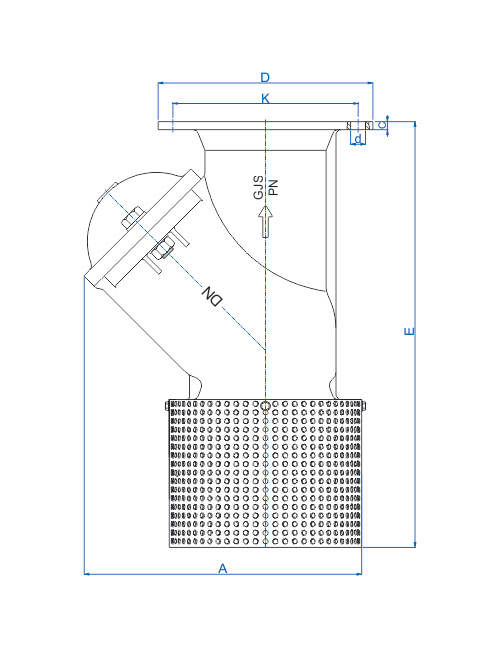

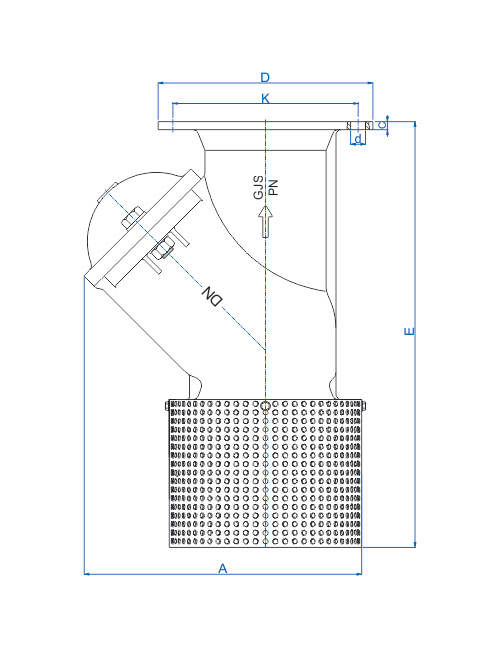

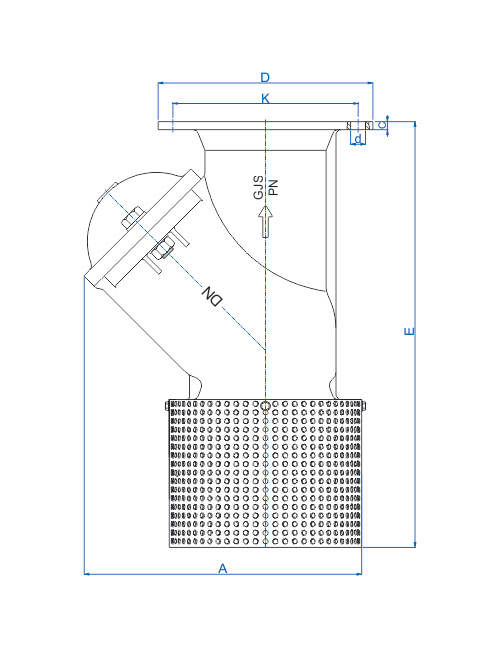

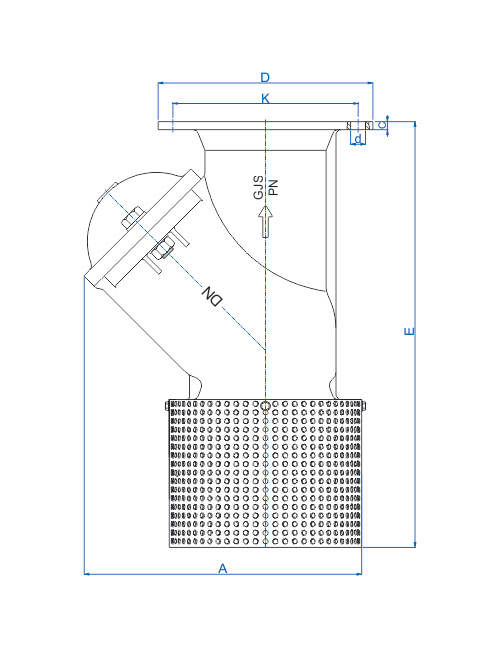

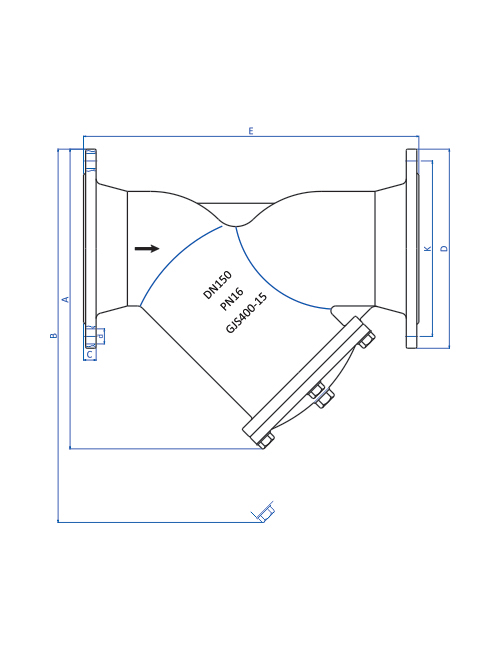

It is used in industrial, agricultural and water line systems, potable water and pump stations for non-corrosive liquids with maximum temperature of 80oC in order to prevent suspended particles enter the water network

It is used in industrial, agricultural and water line systems, potable water and pump stations for non-corrosive liquids with maximum temperature of 80oC in order to prevent suspended particles enter the water network- Flanges Drilled according to EN 1092-2 and other standards upon request

- Flanges face-to-face length according to (EN558-1) DIN3202-1

- Body made of ductile iron EN1563(GJS400)

- Stainless steel filter AISI304 according to DIN17440

- Inside and outside surfaces of ductile iron parts covered with a minimum of 250 micron epoxy electrostatic method coating according to DIN30677